Ferro Scanning Test:

At a selected location on the RCC members of the structures covered under the study see the adequacy of concrete cover to rebars and effect of carbonation.

In any RCC/PSC structure, adequate cover thickness is essential to prevent corrosion of the reinforcement. In old structures, sometimes the detailed drawings are not traceable due to which it becomes very difficult to calculate the strength of the structure which is essentially required for finalizing the strengthening scheme. Sometimes, the bridges are to be checked from strength point of view to permit higher axle load and in absence of reinforcement details it becomes very difficult to take a decision.

To overcome all these problems, the methods have been developed for investigation and evaluation of concrete structures. PS200 is a small versatile instrument for detecting location, size of reinforcement and concrete cover. This instrument is also known as rebar locator. This is a portable and handy instrument which is normally used to locate the reinforcement on LCD display.

Object:

This test is used to assess the location and diameter of reinforcement bars and concrete cover. This equipment can be used effectively for evaluation of new as well as old structures. The method can be used both for quality control as well as quality assurance.

Principle:

The system employs the magnetic resonance principle to detect the reinforcing bars. The scanner generates a magnetic field and interprets the variations in magnetic resonance caused by the reinforcing bars within this field. The position and diameter of the bars, as well as the depth of concrete cover over them, can thus be determined at any desired location on the structure.

PS 200 Instrument :

Tools incorporating the latest detection technologies have become indispensible in everyday construction work. Cordless detection systems now help to make steel rebars in concrete visible – quickly, easily and without need for destructive procedures.

Detection systems come into their own, above all, in situations where existing structures require to be monitored or where the need for repair must be assessed without resorting to destructive procedures.

Detection systems such as the Hilti Ferroscan PS200 locate reinforcing bars under the concrete surface in bridges and other structures.

These systems are capable of determining the number of rebars present, their positions, depths and diameters, and can provide a reliable image of the concealed reinforcement simply by scanning over the surface of the structure.

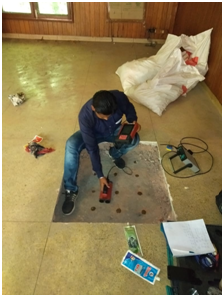

Cordless detection systems such as the Ferroscan PS200 from Hilti consist of a scanner, monitor unit and PC software. After passing the scanner over the surface of the structure, the positions of the reinforcing bars can be marked directly on the concrete or the applicable data recorded and transferred right away, on site, to the portable monitor unit for viewing and evaluation. The system can help to rule out the possibility of damage to steel reinforcement. Costly delays and damage to rebars as a result of hammer drilling or core drilling can be avoided and the holes to be drilled can be positioned accurately and correctly right from the beginning. The data provided by this system thus saves time and cuts costs.

With its Quickscan function, the Ferroscan PS200 is capable of scanning a section up to 30m long in a single, continuous pass, during which it records the depth of concrete cover over the uppermost reinforcement layer. This has proved very effective, especially on bridges, where the minimum depth of concrete cover is a critical factor and where this data is required for quality control, for example, with precast concrete components.